Introduction

As global manufacturing moves toward high-mix, high-precision production, 5-axis machining has become an essential capability for achieving complex geometries, superior accuracy, and reduced cycle times. However, the true potential of 5-axis machining centers lies not only in the machine itself but also in the precision accessories that drive their versatility — one of the most critical being the CNC rotary table.

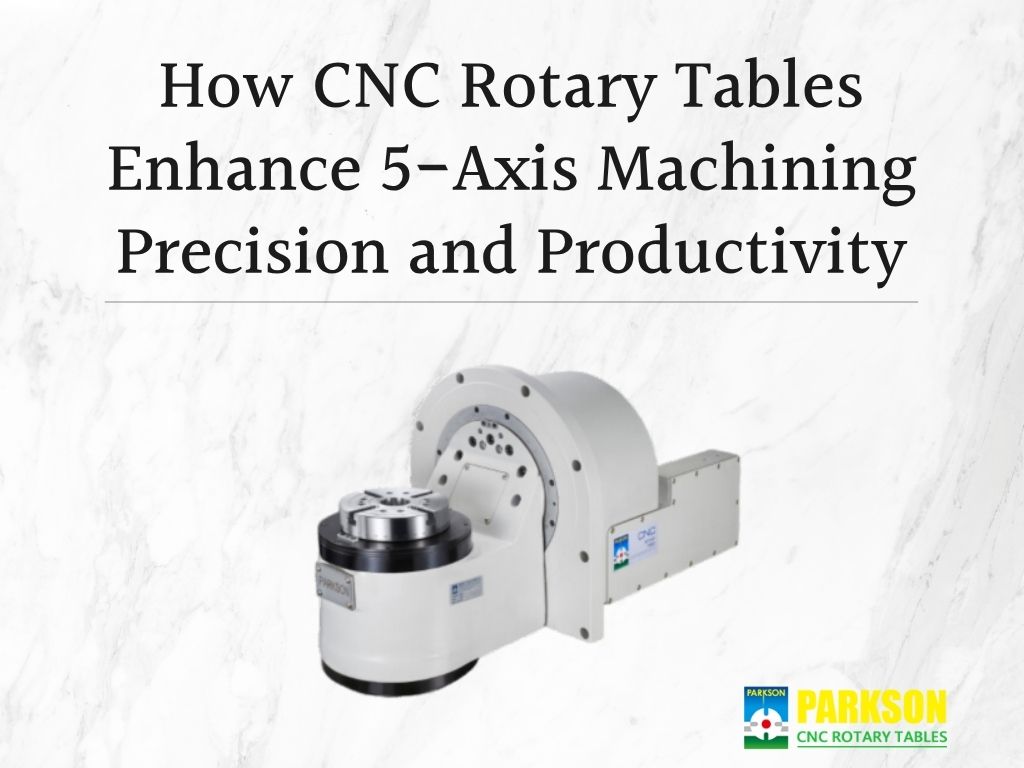

At PARKSON, we specialize in developing advanced rotary tables engineered for precision, stability, and speed. Our CNC rotary tables empower manufacturers to perform multi-sided machining, reduce setup time, and deliver outstanding part quality — all while maintaining exceptional repeatability and reliability.

The Role of CNC Rotary Tables in 5-Axis Machining

In a 5-axis setup, CNC rotary tables introduce one or two additional axes (typically the 4th and 5th axes) to a 3-axis machining center. This allows the workpiece to rotate and tilt, enabling tool access from virtually any angle without repositioning.

By integrating a CNC rotary table, manufacturers can:

-

Machine multiple sides in a single setup, eliminating manual re-clamping.

-

Optimize cutting angles for smoother tool engagement and longer tool life.

-

Enhance surface finish by maintaining constant contact between the cutting tool and the workpiece.

-

Achieve tighter tolerances across complex parts like turbine blades, impellers, or molds.

The result is faster machining, reduced error accumulation, and significant improvements in both precision and productivity.

Precision through Advanced Design

PARKSON’s CNC rotary tables are designed to meet the strict demands of modern 5-axis machining. By utilizing high-rigidity structures and precision bearings, our rotary tables minimize deflection even under heavy cutting forces.

For applications requiring extreme accuracy, PARKSON offers direct-drive torque motor rotary tables that eliminate mechanical backlash and deliver smooth, high-speed rotation. The integrated encoder feedback ensures sub-arc-second positioning accuracy, making them ideal for industries such as aerospace, medical, and semiconductor machining where precision is non-negotiable.

Productivity Gains in Multi-Surface Machining

One of the biggest advantages of incorporating a CNC rotary table into a 5-axis system is the dramatic reduction in setup time. With traditional 3-axis machining, operators must repeatedly remove and re-align the workpiece to access different surfaces — a process that not only consumes time but also introduces positioning errors.

CNC rotary tables allow all these operations to be completed in a single setup, maintaining perfect alignment throughout the process. This streamlined workflow enhances throughput and consistency, enabling higher part output without compromising accuracy.

Moreover, in automated environments, CNC rotary tables can be integrated with auto pallet changers (APC) and flexible manufacturing systems (FMS) to achieve uninterrupted production and faster turnaround times.

Real-World Applications

PARKSON’s CNC rotary tables are trusted across a wide range of industries where precision and reliability are essential:

1. Aerospace Components

Complex parts like turbine blades, casings, and housings require multi-angle machining. CNC rotary tables allow continuous contouring for superior aerodynamic surface finishes.

2. Automotive Manufacturing

From engine housings to transmission components, multi-face machining improves part uniformity and reduces cycle time, ensuring cost-effective mass production.

3. Mold & Die Industry

Rotary tables provide high-precision indexing and tilt capability for intricate mold cavities and 3D contour machining, ensuring smooth, defect-free surfaces.

4. Energy and Heavy Equipment

For large, heavy components such as pump bodies or turbine housings, PARKSON’s horizontal CNC rotary tables offer outstanding rigidity and load capacity.

5. Medical and Precision Components

In medical device production, CNC rotary tables ensure consistent accuracy for implants, surgical tools, and miniature components that demand exact tolerances.

PARKSON CNC Rotary Table Solutions

At PARKSON, our CNC rotary table lineup is engineered to support a variety of machining requirements:

-

MNCD Series – CNC Rotary Table

Provides flexible rotary positioning and multi-surface machining for complex geometries. Works seamlessly with X/Y/Z axes for efficient 4-axis contouring. -

PARD Series (1/2/3 DD-Motor CNC Tilting Rotary Tables)

Equipped with high-torque direct-drive motors, these models deliver zero backlash, ultra-smooth motion, and simultaneous dual-axis control for advanced 5-axis machining. -

HMCD Series – CNC Rotary Table

Built for heavy-duty applications, combining strong clamping systems with high load-bearing capacity to maintain stability under high cutting forces.

Each PARKSON rotary table integrates seamlessly with most CNC machining centers, enabling smooth coordination between rotary and linear movements for complex contouring and high-speed positioning.

Enhancing 5-Axis Machining with Direct-Drive Technology

Modern 5-axis machining increasingly relies on direct-drive (torque motor) rotary tables. Unlike traditional worm gear systems, direct-drive technology transmits motion directly from the motor to the table, eliminating mechanical play and achieving true zero backlash.

Benefits include:

-

Higher rotational speed for faster indexing and reduced idle time.

-

Superior surface finish thanks to ultra-smooth motion control.

-

Lower maintenance requirements since there are no gears to wear out.

PARKSON’s torque-driven rotary tables exemplify this evolution, delivering unmatched dynamic performance that supports the growing demand for precision automation.

Conclusion

CNC rotary tables are at the heart of 5-axis machining excellence. They empower manufacturers to produce complex parts faster, with greater precision and consistency — transforming how industries approach high-value production.

At PARKSON, we are committed to helping manufacturers unlock their full machining potential. Our comprehensive line of CNC rotary tables — from the versatile MNCD series to high-torque direct-drive models — offers the accuracy, durability, and innovation required to stay ahead in today’s competitive market.

✉ Contact us today to learn more about PARKSON CNC rotary tables and discover how our solutions can elevate your 5-axis machining performance.